| Capability Title |

Catalytic process development and blendstock production |

| Laboratories |

Los Alamos National Laboratory (LANL), National Renewable Energy Laboratory (NREL), Pacific Northwest National Laboratory (PNNL), Sandia National Laboratories (SNL), Idaho National Laboratory (INL) |

| Capability experts |

Vanessa Dagle (PNNL), Ryan Davis (SNL), Karthi Ramasamy (PNNL), M.M. Ramirez-Corredores (INL), Dan Ruddy (NREL), Andrew Sutton (LANL) |

| Description |

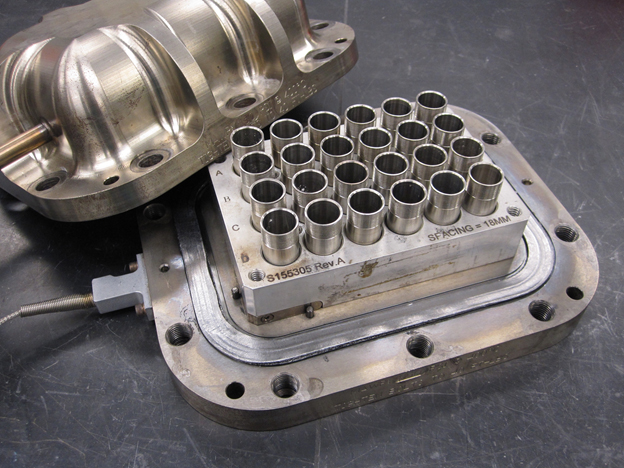

- High throughput batch system for accelerated catalyst synthesis: synthesize 48 catalysts at once, operating temperature up to 400°C and pressure up to 3000psig

- High throughput batch system for accelerated catalyst testing in condensed/liquid phase: screen 48 catalysts/run, operating temperature up to 400°C and pressure up to 3000psig.

- High throughput continuous flow system for gas phase catalyst testing which can screen 16 catalysts/run, test catalysts in a bed with volume up to 1.5 mL at an operating temperature up to 500°C and pressure up to 2000psig, with on-line gas products analysis.

- Lab scale continuous flow reactor systems for gas phase and liquid phase reactions including dehydration, carbon-carbon coupling, integrated oligomerization and hydrogenation. Catalyst loading volume up to 20 mL, operating temperature up to 700°C and pressure up to 2500psig. On-line gas phase products analysis combined with off-line GC-MS, HPLC, GC-FID analysis for optimal products identification and quantification. Can be operated in conjunction with on-site fuel property characterization capabilities including ignition quality testing, vapor pressure, simulated distillation, freezing point, etc.

- Hydrocarbon fuels distillation at scales from 10mL to 3L, including vacuum distillation for low-boiling range products.

- Catalyst design for specific process development.

- Low temperature, high conversion approaches for selective transformations

- Low volume fuel property testing (<25 mL) for primary fuel properties

- Non-precious metal catalysts for high carbon yielding conversions

|

| Limitations |

Scales from µL to 20mL catalyst bed volume

Operating temperature, pressure and throughput limits are specific to each system throughout the National Lab complex. |

| Unique aspects |

High-throughput catalyst screening systems provide both flow and batch reactor capabilities. Strong coupling to computational chemistry capabilities generates new insights into catalysts and reactions not available from experimentation alone. Low temperatures highly selective conversion technologies minimize energy requirements. |

| Availability |

Heavily utilized; additional activities can be accommodated with proper planning |

| Citations/references |

High Throughput Center: https://www.chemcatbio.org/pdfs/ccb_pnnl_high_throughput_center.pdf |