| Capability Title |

Thermochemical process development |

| Laboratories |

Idaho National Laboratory (INL), National Renewable Energy Laboratory (NREL), Pacific Northwest National Laboratory (PNNL) |

| Capability experts |

Thomas Foust (NREL), Dan Gaspar (PNNL), M.M. Ramirez-Corredores (INL), Vicki Thompson (INL) |

| Description |

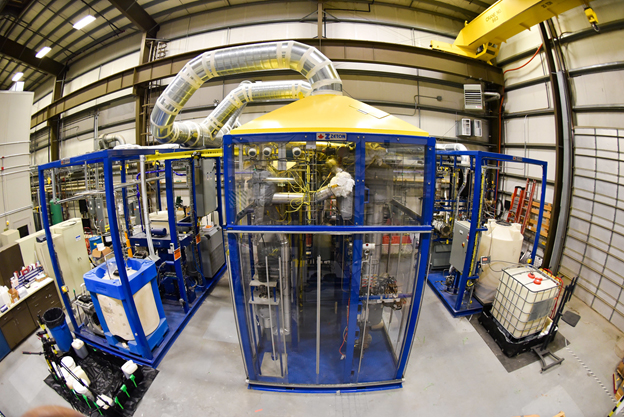

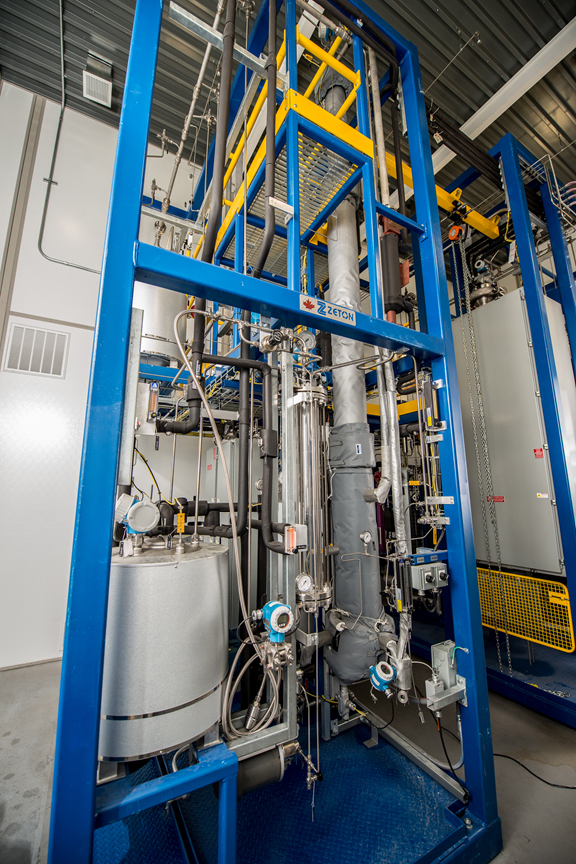

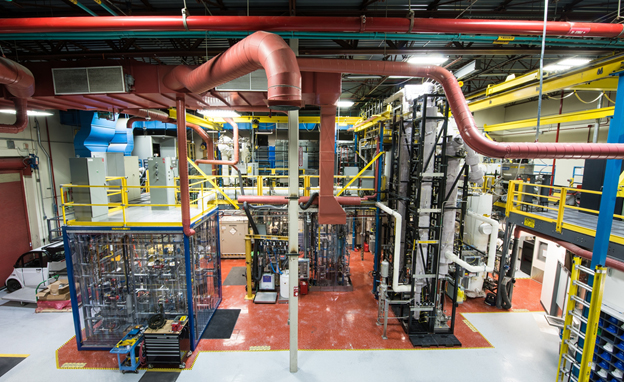

- PNNL’s Modular Hydrothermal Liquefaction System is a continuous hydrothermal liquefaction system incorporating feedstock pretreatment, HTL conversion and product separation capabilities. The system can incorporate hydrothermal gasification capabilities, as well.

- HTL operation up to 3000 psig and 660°F.

- Product separation at 30-180L scale that can run continuously at 4-16L/hr

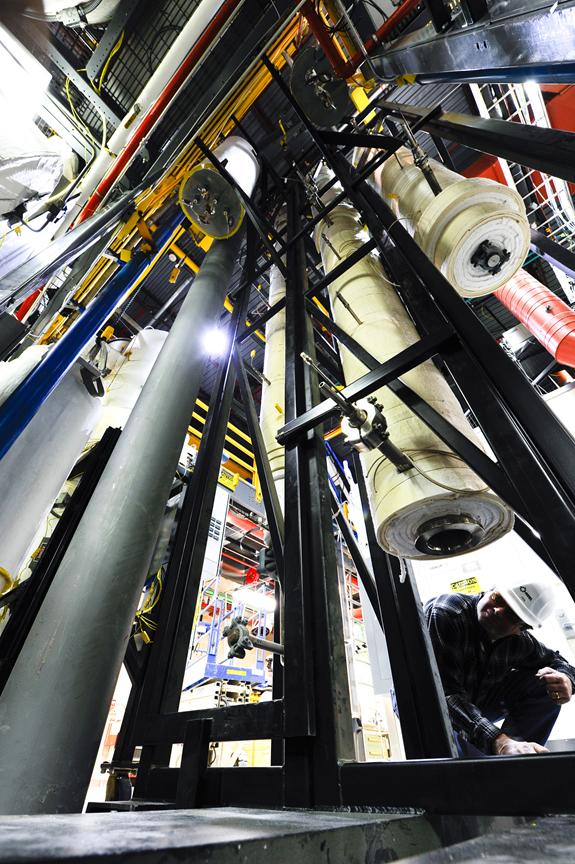

- Bench- and engineering-scale HTL oil hydrotreating systems to remove O, S and N include:

- Several scales and modes of continuous flow hydrotreaters.

- Four lab-scale down-flow trickle beds allow for unattended operation with a biocrude feed rate of 3 to 25 mL/hr.

- Two bench-scale hydrotreaters, a fixed bed and a moving bed, allow a feed rate of 40 to 250 mL/hr.

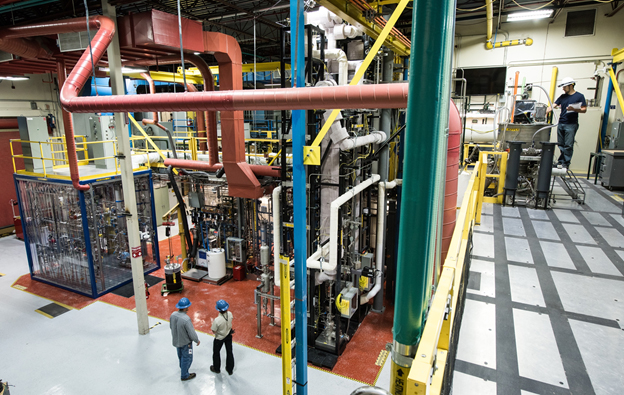

- Catalytic upgrading of bio-oil in the vapor phase allows for the selection of higher value chemicals and oil products. NREL recently installed a Davison Circulating Riser (DCR) reactor system integrated with their 1/2 ton/day pilot plant. The DCR is coupled with a biomass pyrolyzer for catalytic deoxygenation of pyrolysis vapors to produce hydrocarbons and high-value oxygenates.

- The NREL Thermochemical Process Development Unit (TCPDU) can either operate in gasification or pyrolysis mode. In gasification mode it converts solid biomass to clean, compressed syngas (H2 and CO) in one system. The NRG typically operates between 3 and 5 m3/hour, and consists of a continuous biomass feeder, bubbling fluidized bed gasifier, cyclone char removal, hydrocarbon steam reformer, CO2 amine scrubber, and gas compression to provide high-pressure syngas (>2,000 psig) to any system.

- In pyrolysis mode the TCPDU converts ½ ton/day into pyrolysis oil and utilizes a U-tube reactor to produce pyrolysis vapors which are quenched in a specialty designed quench system.

- Advice for technology scale up from research to technology implementation at commercial scale.

- Feedstock design, selection and preparation under consistent specifications

|

| Limitations |

Large quantities of feedstock or hydrocarbon feed are required |

| Unique aspects |

Pilot scale facilities enable production of biofuels in volumes sufficient for fuel performance characterization |

| Availability |

Capabilities are available with enough advance planning |

| Citations/references |

https://www.pnnl.gov/process-development-units

https://www.nrel.gov/docs/fy13osti/58532.pdf

https://www.nrel.gov/docs/fy15osti/63127.pdf

https://www.nrel.gov/bioenergy/thermochemical-integration-scale-up-piloting.html |